Novel (3D) Neutron Imaging Technique for Nondestructive Testing Made Possible by Large-Area, Intensified CCD Camera System

Introduction

Every engineer and scientist dreams of being able to investigate objects from within, without destroying them, in order to study cracks, hidden flaws, or structural material changes. Over the years, a variety of technologies have been utilized to help make this dream a reality via the ongoing development of new techniques that leverage the unique characteristics of different radiation modalities.

Unfortunately, the most common modality, visible light, cannot be used to realize this vision of investigating objects from within. Visible light only provides an opaque view of an object’s outer surface, since it is reflected from or absorbed by the surface of most materials (with a few notable exceptions, such as water and glass).

Partial or full object transparency can be achieved by other modalities though, including x-rays, ultrasound, microwaves, and infrared radiation. Of all such modalities, x-rays are probably the most well known owing to their use in many medical, industrial, and scientific applications. The specific characteristics of the x-rays utilized (i.e., wavelength / energy, and intensity / flux) are selected according to sample composition and investigative goals.

In this application note, we will discuss another radiation modality, neutrons. Free neutrons are produced solely by nuclear reactions. Besides their use for energy production in nuclear reactors, neutrons are essential probes for materials research on atomic and molecular length scales. They are proving very useful for a growing range of nondestructive investigations, offering engineers and scientists a powerful complement to x-rays. Neutrons, which penetrate thick-walled samples, actually travel similarly to x-rays but interact differently with matter than x-rays do.

Basic Neutron Radiography

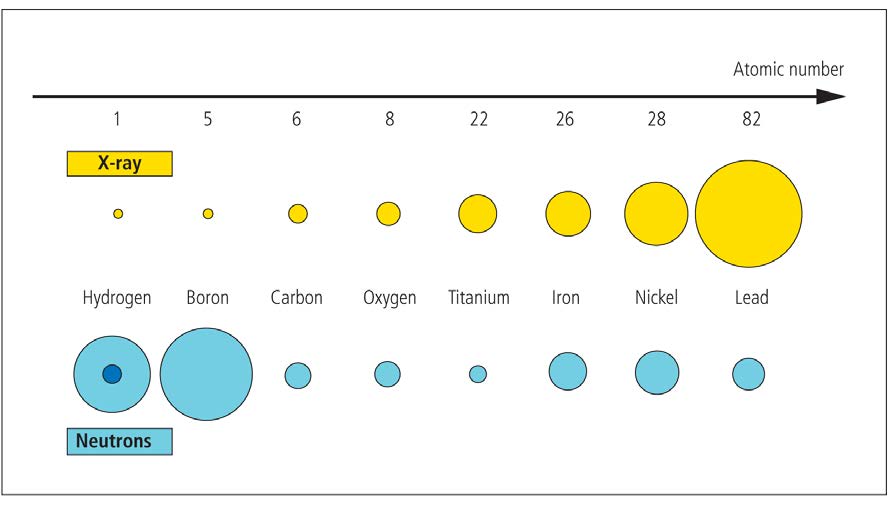

As a result of their interactions with matter, neutrons, like x-rays, provide an image of transmitted radiation (i.e., a neutron radiograph). Unlike x-ray interactions, however, which are highly dependent on the atomic number of the matter, neutron interactions do not depend on the atomic number. For instance, although lead effectively shields x-rays, it is practically transparent to neutrons. Because x-rays and neutrons interact differently with matter, these two radiation modalities highlight complementary properties of an object’s internal structure.

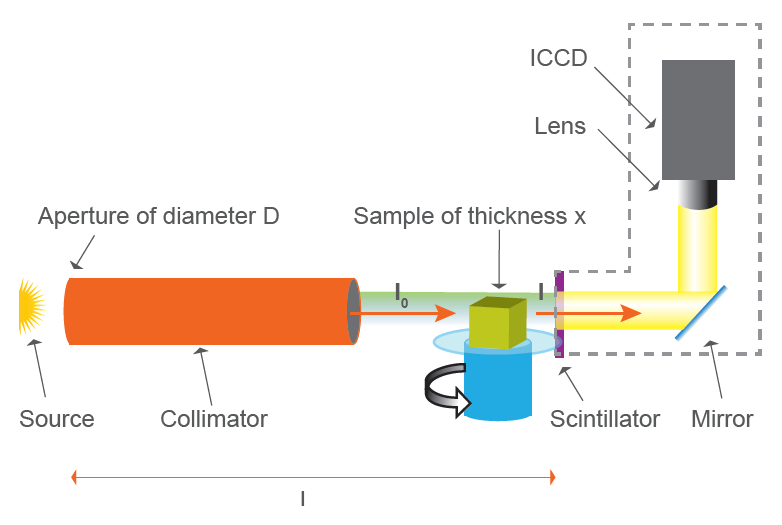

For neutron radiography, neutrons are detected mainly using special area detectors that provide digital images with high sensitivity and high spatial resolution. See Figure 1.

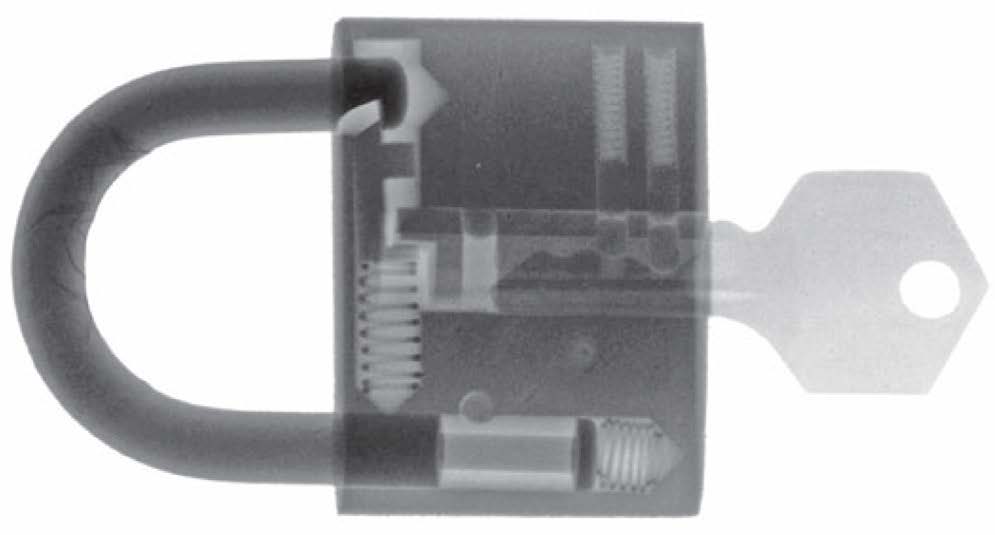

Neutron radiography is used for nondestructive investigations / testing in a wide range of scientific and industrial applications. Figure 2 shows the neutron radiography of a lock. The material composition and the thickness yield different image contrasts, illuminating the individual components of the lock as well as detecting any component flaws or possible assembly errors.

Dynamic Neutron Radiography (dNR)

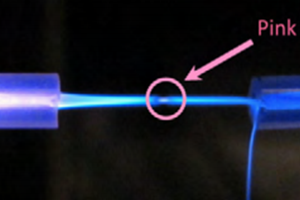

Dynamic neutron radiography is utilized for time-dependent, nondestructive investigations. This approach enables engineers and scientists to acquire real-time data and observe the inner workings of a system whose components often cannot be seen using other radiation modalities, such as x-rays. A typical setup for such investigations is similar to that shown in Figure 1, although the ICCD camera intensifier’s gating must be synchronized with the periodicity of the system (e.g., a running engine) under study.

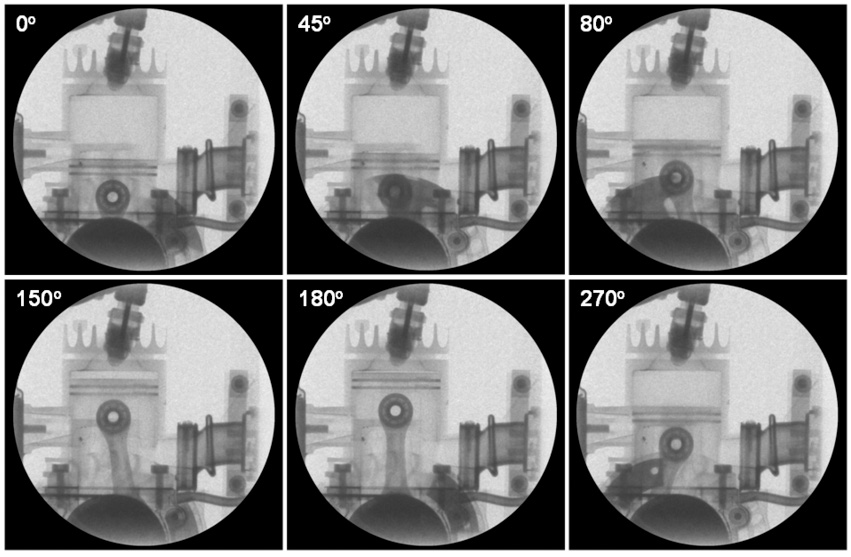

Running engines present a prime example of such investigations. Their rapid periodic processes can be observed via a chronological series of precisely triggered, short exposures. Figure 3, for example, shows three dynamic neutron radiography images of a running motorcycle engine driven by an electric motor.

Dynamic neutron radiography has also been utilized to observe the real-time dispersion of lubricant oil within a functioning motorcycle clutch. Researchers explain that while x-rays are strongly absorbed by the metal and the lubricant is barely visible, it is the exact opposite with neutrons: the metal is transparent and the oil absorbs the neutrons1.

Figure 4 shows dynamic neutron radiography measurements of a two-stroke chainsaw engine running at 8000 rpm. The frames show different crankshaft positions of a fully recorded rotation. The exposure time of a single raw image was 50 microseconds.

show 6 out of 72 different crankshaft positions for a chainsaw running at 8000 rpm, produced with an exposure time of 50 microseconds. Images acquired using a Princeton Instruments PI-MAX:1300 ICCD camera. Courtesy of Paul Scherrer Institut, Switzerland.

New Technology

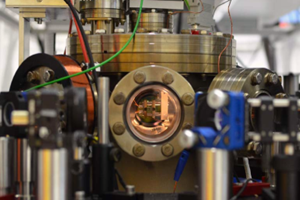

Princeton Instruments recently introduced a new member of its PI-MAX®4 family of scientific ICCD cameras, the PI-MAX4:2048f (see Figure 5), which is ideal for dynamic neutron radiography. The PI-MAX4:2048f provides four times the imaging area of any other commercially available intensified CCD camera. This larger imaging area enables the collection of more data per image, a critical advantage given the cost of operating a neutron source.

The highly sensitive PI-MAX4:2048f, which features a 2k x 2k CCD fiberoptically coupled to one of several Gen II or Gen III filmless intensifiers, is the only ICCD camera on the market today to offer high frame rates at 6 MHz / 16-bit digitization, as well as a 1 MHz sustained gating repetition rate. An integrated programmable timing generator, SuperSynchro, built into the new camera makes it perfect for dynamic neutron radiography.

efficiently.

Furthermore, the latest Princeton Instruments LightField® data acquisition software, available as an option, affords complete control over all PI-MAX4 hardware features via an exceptionally intuitive user interface. LightField provides automatic defect correction, precision exposure control, and a host of innovative functions for easy capture and export of neutron imaging data.

Summary

Neutron radiography offers an excellent complement to x-ray imaging for a diverse range of nondestructive investigations, including materials research, nuclear technology, paleontology, archaeology, and hydrogeology. Likewise, dynamic neutron radiography complements the x-ray modality in time-dependent, nondestructive investigations such as those related to combustion engines, fuel cells, and two-phase flow systems.

The new PI-MAX4:2048f from Princeton Instruments allows engineers and scientists to utilize dynamic neutron radiography more efficiently, and more cost effectively, by providing the largest imaging area available in a high-sensitivity, precision-gated ICCD camera. The benefits of neutron imaging for scientific and industrial applications will continue to grow as the need to ‘see past’ metallic components and observe small amounts of organic materials keeps increasing.

Acknowledgements

Princeton Instruments wishes to thank Paul Scherrer Institut2 (PSI), Switzerland, as well as Dr. Christian Grünzweig of the Neutron Imaging and Activation Group at PSI, for providing key information contained in this document.

References

- Grünzweig C., Wagner M., Ruf J., and Helmer D., “Visualization of the oil distribution in a wet-running multi-disc clutch by dynamic neutron radiography,” ATZ 115(4):224 (2013).

- http://www.psi.ch/niag/

Neutron Radiography Fundamentals

X-ray radiography, or x-ray imaging, is well known and widely utilized within the medical field to study the human body. It is also gaining

acceptance for various materials science applications in which nondestructive testing (NDT) is required. Neutron radiography techniques, though complementary to x-ray techniques, are not as widely used, owing primarily to the requirement for a highly specialized and secured testing facility. Neutron radiography, however, is an essential tool for NDT when x-ray radiography fails (e.g., for transmission through heavy metal samples or detection of small amounts of hydrogen within a metallic base material).

The principles of neutron and x-ray radiography measurements are basically the same, except for the different radiation sources and the respective radiation’s interactions with matter. Neutrons are neutral particles (i.e., particles without electrical charge). Along with positively charged protons, neutrons are the building blocks of the atomic nucleus. A free neutron is not stable; it is a radioactive particle with a mean lifetime of about 15 minutes. After that time, it decays into a proton, simultaneously emitting an electron and an anti-neutrino.

The interaction of a free neutron with an atom is quite different than that of an x-ray and is not influenced by the atom’s electron cloud. Therefore, a free neutron can penetrate deeply into matter. The free neutron will react with the atomic nucleus differently based on the nucleus’ isotopic composition and neutron energy. Some atomic nuclei (e.g., boron, lithium, cadmium, and gadolinium) absorb free neutrons incident at low speed.

Due to this absorption property, such elements can be used as shielding materials, or for neutron detection. Other atomic nuclei (e.g., aluminum and lead) are almost transparent to free neutrons because they interact weakly with them. There are also some nuclei that induce a deviation of the incident free neutrons from a straight trajectory, producing neutron-scattering reactions. Occurring in most isotopes, they are especially strong in hydrogenous materials.

Neutrons, similar to other elementary particles, act not only like particles but also like waves. They are subject to the same laws of optics that apply to light (i.e., an index of refraction showing the effects of diffraction or interference accurately describes some neutron interactions with matter).

In materials research applications, either thermal or cold neutrons are utilized because their energies / wavelengths are appropriate for elucidating the structure and dynamics of solid-state or soft matter. Neutron detection reactions yield high probabilities at low neutron energies; therefore, high-spatial-resolution detectors that provide very high sensitivity are essential to neutron imaging.